Tianjin Xuansheng Technology Co.,Ltd.

Products name: ABS pump control module precision mold insert injection molding

Products materials: PBT+GF30

Products surface: polishing

Products color: black

Mold quantity for whole set products: 4 mold

Mold structure: insert mold

Mold steel: 8407

Mold cavity: 1*2

Runner: Hot runner

Mold working life: 1 million shot time

suitable machine tonnage: 160-280 tonnage for different mold

Email: sales@txs-mold.com

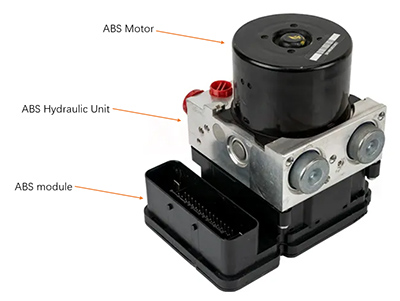

ABS pump is very important part for the automotive. It's combined by 3 parts, ABS MOTOR, ABS Hydraulic Unit, and ABS module.

ABS pump control module precision mold belong to insert mold technology, it's insert injection molding metal pin with plastic parts. Tianjin xuansheng technology have rich experience in this area. The whole sets of ABS pump control module is insert injection molding by 4 precision mold. The ABS pump control module adopt PBT + 30GF, which are very difficult to be molding. Tianjin Xuansheng technology master the special injection technology, T-0 mass production is our principle.

ABS pump control module precision mold belong to insert mold technology, it's insert injection molding metal pin with plastic parts. Tianjin xuansheng technology have rich experience in this area. The whole sets of ABS pump control module is insert injection molding by 4 precision mold. The ABS pump control module adopt PBT + 30GF, which are very difficult to be molding. Tianjin Xuansheng technology master the special injection technology, T-0 mass production is our principle.

The ABS module is the controller of the entire ABS system. It's a black box bolted to the top of the ABS unit, and it reads wheel speed, vehicle acceleration, braking force, brake fluid pressure, longitudinal and lateral acceleration, and information transmitted from the engine and transmission systems. The ABS module then calculates the precise braking force required for each wheel under emergency braking conditions and controls each wheel by operating control solenoids within the ABS hydraulic block. ABS modules commonly fail and cause communication problems, internal control module fault codes, or sometimes cause the ABS motor to keep running.

Following is some parameter of the molds:

| Products name: | ABS pump control module precision mold insert injection molding |

| Products materials: | PBT+GF30 |

| Products surface: | polishing |

| Products color: | black |

| Mold quantity for whole set products: | 4 mold |

| Mold structure: | insert mold |

| Mold steel: | 8407 |

| Mold cavity: | 1*2 |

| Runner: | Hot runner |

| Mold working life: | 1 million shot time |

| Molding machine specification: | 160-280 tonnage for different mold |